Top 5 process improvement methodologies: The pros and cons

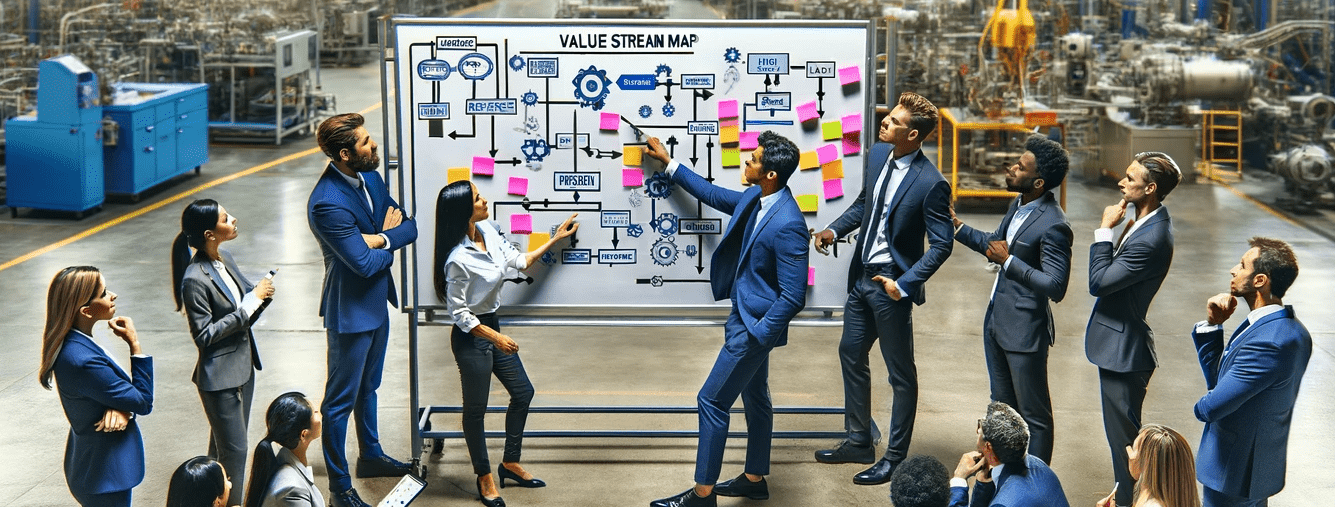

In today’s competitive business landscape, organizations are constantly seeking ways to improve their processes and streamline operations. Process improvement methodologies provide structured approaches to identifying inefficiencies, optimizing workflows, and driving overall business growth. In this article, we will explore the top 5 process improvement methodologies, discuss their pros and cons, and evaluate their suitability for different organizational needs.

What is a process improvement methodology?

Before diving into the specifics of the top 5 process improvement methodologies, let’s first understand what a process improvement methodology entails. In essence, a process improvement methodology is a systematic and data-driven approach that aims to enhance the efficiency and effectiveness of business processes.

When it comes to running a successful business, it’s crucial to constantly evaluate and improve processes. This is where process improvement methodologies come into play. These methodologies provide organizations with a framework to identify bottlenecks, eliminate waste, improve customer satisfaction, and create a culture of continuous improvement.

By adopting a process improvement methodology, businesses can optimize their operations to achieve higher productivity, better quality outcomes, and increased profitability. It’s all about finding ways to work smarter, not harder.

The five process improvement methodologies in short

One popular process improvement methodology is Lean Six Sigma. This methodology combines the principles of Lean, which focuses on eliminating waste and improving flow, with Six Sigma, which aims to reduce defects and variations in processes. By using Lean Six Sigma, organizations can streamline their processes, reduce costs, and improve customer satisfaction.

Another widely used process improvement methodology is Business Process Reengineering (BPR). BPR involves rethinking and redesigning existing processes to achieve significant improvements in performance. It often involves radical changes and is best suited for organizations looking to make transformative changes to their operations.

Agile is yet another process improvement methodology that has gained popularity in recent years, particularly in software development. Agile focuses on iterative and incremental development, allowing teams to adapt and respond to changing requirements and customer needs. It promotes collaboration, flexibility, and continuous improvement.

Six Sigma, on its own, is also a powerful process improvement methodology. It emphasizes the use of statistical analysis to identify and eliminate defects in processes. By reducing variations and improving process stability, organizations can achieve higher levels of quality and customer satisfaction.

Lastly, the Theory of Constraints (TOC) is a process improvement methodology that focuses on identifying and managing constraints or bottlenecks in processes. By addressing these constraints, organizations can improve overall system performance and achieve better outcomes.

Overall, process improvement methodologies provide organizations with the tools and techniques to analyze, optimize, and continuously improve their processes. By adopting these methodologies, businesses can stay ahead of the competition, deliver better products and services, and ultimately, achieve long-term success.

Now, let’s explore the five methodologies in more detail in the next section.

Examples of process improvement features

Review and Update Process

Process outcome: All processes reviewed and updated.

Reusable process and activity components

Insert any existing activity or process into another for reuse and cross-functional consistency.

Streamlining Processes with the Top 5 Process Improvement Methodologies

When it comes to selecting the most suitable process improvement methodology for your organization, it’s essential to understand the strengths and weaknesses of each approach. Let’s take a closer look at the top 5 process improvement methodologies:

1. Lean Six Sigma

Lean Six Sigma is a powerful methodology that combines the principles of Lean manufacturing and Six Sigma to improve process efficiency and reduce defects. The Lean approach focuses on eliminating waste and non-value-added activities, while Six Sigma aims to minimize process variation and enhance quality.

By adopting Lean Six Sigma, organizations can experience a range of benefits. Increased customer satisfaction is one of the most significant advantages, as the methodology ensures that processes are streamlined to meet customer needs effectively. Additionally, Lean Six Sigma can lead to reduced costs by eliminating unnecessary steps and optimizing resource allocation. Furthermore, employee engagement is enhanced as they are empowered to identify and solve problems, contributing to a more positive work environment.

However, it’s important to note that implementing Lean Six Sigma may require substantial training and resources. The methodology heavily relies on data accuracy and analysis, which can be challenging for organizations without a robust data infrastructure. Additionally, sustaining the results achieved through Lean Six Sigma requires ongoing commitment and continuous improvement efforts.

2. Agile

Originally developed for software development projects, Agile has gained popularity as a process improvement methodology in various industries. Agile emphasizes collaboration, iterative development, and the ability to quickly adapt to changing requirements.

Agile offers several benefits to organizations. Improved project visibility is a significant advantage, as Agile methodologies promote transparency and regular communication among team members. This increased visibility enables better tracking of progress and early identification of potential issues. Additionally, Agile methodologies enable faster time-to-market, allowing organizations to respond quickly to market demands and gain a competitive edge. Moreover, Agile fosters increased customer responsiveness by involving them throughout the development process, ensuring that their feedback is incorporated into the final product.

However, Agile may not be suitable for organizations with rigid hierarchies and traditional project management practices. Adopting Agile requires a significant shift in mindset, as it emphasizes self-organizing teams and adaptive planning. Additionally, Agile methodologies may require organizations to invest in training and coaching to ensure successful implementation.

3. Business Process Reengineering

Business Process Reengineering (BPR) seeks to radically redesign processes to achieve significant improvements in performance and efficiency. BPR involves questioning existing practices, challenging assumptions, and fundamentally rethinking how work is done.

Implementing BPR can offer organizations several advantages. One of the key benefits is the potential for breakthrough performance improvements. By questioning existing processes and challenging assumptions, organizations can identify and eliminate inefficiencies, leading to substantial gains in productivity and cost reduction. Additionally, BPR can simplify processes by removing unnecessary steps and streamlining workflows. This simplification can enhance organizational agility, enabling faster response times and better adaptation to changing market conditions.

However, it’s important to note that BPR may face resistance from employees, as it often involves significant changes to their roles and responsibilities. The disruptive nature of BPR can create uncertainty and resistance to change, requiring effective change management strategies to ensure successful implementation. Additionally, BPR can be a time-consuming undertaking, requiring thorough analysis and planning to achieve the desired outcomes.

4. Total Quality Management (TQM)

Total Quality Management (TQM) is a holistic approach that focuses on continuous improvement, customer satisfaction, and employee involvement. TQM incorporates quality principles such as process standardization, error prevention, and ongoing measurement and feedback.

Adopting TQM can result in several strengths for organizations. Improved product quality is a significant advantage, as TQM methodologies emphasize error prevention and continuous improvement. By standardizing processes and implementing quality control measures, organizations can reduce defects and enhance customer satisfaction. Additionally, TQM fosters increased customer loyalty by consistently delivering high-quality products and services. Moreover, TQM promotes a culture of quality consciousness, where employees are actively involved in identifying and addressing process inefficiencies.

However, implementing TQM requires strong leadership commitment and support. The successful adoption of TQM relies on leaders who champion quality initiatives and create a culture that values continuous improvement. Additionally, it’s important to note that TQM may take time to yield measurable results, as it involves ongoing measurement and feedback to identify areas for improvement.

5. Kaizen

Derived from the Japanese term for “continuous improvement,” Kaizen involves small, incremental changes to processes over time. Kaizen encourages employee involvement, teamwork, and a keen focus on identifying and addressing inefficiencies.

Organizations can experience several benefits by embracing Kaizen. Increased employee empowerment is a significant advantage, as Kaizen methodologies encourage employees at all levels to contribute ideas and suggestions for process improvement. This empowerment fosters a sense of ownership and engagement, leading to a more motivated workforce. Additionally, Kaizen enables ongoing problem-solving capabilities, as employees are encouraged to identify and address inefficiencies on an ongoing basis. Moreover, Kaizen promotes a culture of continuous learning, where employees are encouraged to seek opportunities for improvement and share knowledge and best practices.

However, it’s important to note that Kaizen may not be suitable when organizations require radical transformations or quick process overhauls. The incremental nature of Kaizen may not be sufficient to address significant process deficiencies or when organizations need immediate results. Additionally, successful implementation of Kaizen requires a supportive organizational culture that values employee input and encourages collaboration.

“What gets measured gets improved.”

Peter Drucker

Evaluating the Benefits and Drawbacks of 5 Popular Process Improvement Strategies

As organizations consider adopting a process improvement methodology, it’s crucial to evaluate the benefits and drawbacks of each approach thoroughly. Here is a summarized comparison of the pros and cons of the top 5 process improvement methodologies:

| Process Improvement Methodologies | Pros | Cons |

| Lean Six Sigma | Increased customer satisfaction, reduced costs, enhanced employee engagement | Requires substantial training and resources, results reliant on accurate data analysis |

| Agile | Improved project visibility, faster time-to-market, increased customer responsiveness | May not suit organizations with rigid hierarchies, requires mindset and project management paradigm shift |

| Business Process Reengineering | Potential for breakthrough performance improvements, simplified processes, increased organizational agility | Employee resistance, time-consuming and disruptive |

| Total Quality Management (TQM) | Improved product quality, increased customer loyalty, culture of quality consciousness | Requires strong leadership commitment, time to yield measurable results |

| Kaizen | Increased employee empowerment, ongoing problem-solving capabilities, culture of continuous learning | May not suit radical transformations or quick process overhauls |

👉 Recommendation: Before selecting a process improvement methodology, it is essential to carefully assess your organization’s needs and challenges. To complement your methodology selection, consider our BPM Software Selection Guide to identify tools that align with your improvement goals. The optimal strategy depends on your organization’s unique context and objectives, and a thoughtful evaluation of these methodologies is crucial before making a decision.

A Comparison of the Benefits and Risks of the Top 5 Process Improvement Methodologies

When deciding on the most suitable process improvement methodology for your organization, consider your specific goals, culture, and resources. Each methodology has its unique advantages and challenges. By understanding the pros and cons of the top 5 process improvement methodologies – Lean Six Sigma, Agile, Business Process Reengineering, Total Quality Management, and Kaizen – you can make informed decisions to enhance your processes and drive continuous improvement.

Conclusions

Selecting the right process improvement methodology is a crucial decision that requires a thorough understanding of an organization’s goals, culture, and resources. Each of the top 5 methodologies—Lean Six Sigma, Agile, Business Process Reengineering, Total Quality Management, and Kaizen—offers distinct advantages and challenges. Whether aiming for increased customer satisfaction, faster time-to-market, breakthrough improvements, or a culture of continuous learning, organizations must carefully weigh the pros and cons to make informed decisions that align with their unique needs. By embracing an appropriate methodology, businesses can optimize processes, enhance efficiency, and foster a culture of continuous improvement to stay competitive and achieve long-term success in today’s dynamic business landscape.

Frequently Asked Questions

The Business Process Reengineering (BPR) methodology is particularly well-suited for achieving breakthrough improvements in performance. By questioning existing processes, challenging assumptions, and fundamentally rethinking how work is done, BPR enables organizations to identify and eliminate inefficiencies, leading to substantial gains in productivity and cost reduction. However, it’s important to be aware that BPR may face resistance from employees due to the significant changes it often entails, and effective change management strategies are crucial for successful implementation.

Kaizen, derived from the Japanese term for “continuous improvement,” is an ideal methodology for fostering a culture of continuous learning and employee empowerment. Kaizen involves small, incremental changes to processes over time and encourages employees at all levels to contribute ideas and suggestions for improvement. This methodology enhances employee empowerment, fosters a sense of ownership and engagement, and promotes ongoing problem-solving capabilities. However, it’s essential to note that Kaizen may not be suitable for organizations requiring radical transformations or quick process overhauls.

Successful implementation of Lean Six Sigma, a methodology combining Lean manufacturing and Six Sigma principles, requires careful consideration. To ensure success, organizations should invest in substantial training and resources for employees involved in the process improvement efforts. It’s crucial to establish a robust data infrastructure for accurate data analysis, as Lean Six Sigma heavily relies on data-driven decision-making. Moreover, sustaining the results achieved through Lean Six Sigma demands ongoing commitment and continuous improvement efforts. Organizations should be prepared for a cultural shift towards problem-solving empowerment among employees to fully realize the benefits of this methodology.